In an era where efficiency, precision, and competitive advantage drive success in the textile and garment industry, technology has become a central pillar of transformation. From small boutique studios to large-scale ready-made garment (RMG) factories, smart systems are reshaping how garments are designed, optimized, and produced. Among these technologies, CAD software, fabric spreaders, and auto cutters stand out as invaluable tools that elevate quality, reduce waste, lower cost, and dramatically boost productivity. Combined with holistic solutions like those offered by AutoMac Technology, garment manufacturers can truly unlock the potential of automation in every phase of production. (automactec.com)

In this blog, we’ll explore

- What each technology is and why it matters

- How they improve processes individually

- Their collective impact on performance and competitiveness

- A deeper look at how AutoMac Technology integrates these systems for maximum benefit

- CAD Software: The Foundation of Modern Garment Design

What Is CAD in the Textile Industry?

CAD stands for Computer-Aided Design — software systems used to create, modify, analyze, and optimize garment designs and technical patterns. In the textile and apparel industry, CAD replaces manual drafting and pattern making, enabling designers and engineers to work digitally from concept to production.

Historically, garment patterns were drafted by hand on paper — a painstaking and error-prone process. Today’s CAD systems handle complex technical specification, grading, marker making, and even 3D visualization — all on digital platforms.

Top Benefits of CAD Software

a. Dramatic Reduction in Design Time

With CAD, pattern creation and editing are done via intuitive interfaces and tools. Designers can:

• Modify patterns instantly

• Grade sizes without redrawing

• Save templates for reuse

• Validate designs digitally

This speeds up workflows that used to take hours or days. Quick turnaround from design to production is a major competitive edge in fast fashion. (automactec.com)

b. Consistency and Precision Across Orders

Digital patterns eliminate human inconsistencies found in manual drafting. Once a design is perfected, it can be precisely reproduced multiple times — ensuring uniform quality across batches. This is especially vital for global brands where consistency affects brand identity.

c. Better Fabric Utilization Through Smart Marker Making

Modern CAD systems include marker making software — tools that optimize how patterns are laid out on fabric. Smart markers reduce fabric waste by calculating the most efficient placement of pattern pieces based on fabric width, print direction, and garment orientation.

Reducing material waste directly improves profitability, especially with rising raw material costs.

d. Seamless Integration With Production Systems

CAD doesn’t just stop at design. Many systems integrate with cutting machines and factory management software so that once patterns are finalized, the data flows directly to production, reducing manual input and errors. (automactec.com)

e. Enhanced Collaboration and Digital Documentation

In a global production environment, teams in different locations can work on the same digital designs simultaneously. CAD also allows detailed documentation, ideal for audits, revisions, and compliance reporting.

- Fabric Spreaders: Laying the Groundwork Efficiently

What Is a Fabric Spreader?

A fabric spreader is a machine designed to lay fabric in consistent multiple layers on a cutting table or automated conveyor before cutting. It ensures that fabric is spread smoothly, with the correct alignment, tension, and without wrinkles or distortions — a prerequisite for accurate cutting.

While manual spreading was common in the past, automated spreaders now dominate cutting rooms due to the quality and speed they enable.

Why Fabric Spreaders Matter

a. Consistent Fabric Quality Across Layers

Fabric spreader machines ensure consistency in how material is layered. This affects not only cutting precision but also the quality of stitches and seams during assembly. Uneven layers can cause deviations in cut shapes, leading to defects and costly rework.

b. Higher Spreading Speed and Throughput

Automatic spreaders work faster than teams of operators manually laying fabric. This enables greater throughput in the cutting room — a critical factor for meeting production targets and preventing bottlenecks. (automactec.com)

c. Reduced Labor Costs and Physical Strain

Manual spreading is labor intensive and prone to human fatigue. Automated spreaders reduce reliance on manual labor, alleviate physical strain, and contribute to safer workplace conditions.

d. Optimal Fabric Tension and Minimal Distortion

Good spreader technology maintains ideal tension — a critical factor for knit or stretch fabrics prone to distortion. Proper layering ensures that the final garment measurements are accurate and consistent.

- Auto Cutters: Precision Meets Speed

What Are Auto Cutters in Garment Manufacturing?

Automated cutting machines, often referred to as auto cutters, are CNC (Computer Numerical Control) systems designed to cut stacked layers of fabric with high accuracy based on digital patterns. They replace manual cutting with precise, programmable technology that delivers consistent results at scale.

These machines can handle various materials — woven fabrics, knit fabrics, leather, and even complex textiles with multiple layers.

Key Advantages of Auto Cutters

a. Accuracy That Humans Can’t Match

Auto cutters follow digital pattern instructions with micron-level precision. Whether cutting straight lines, curves, or complex shapes, these machines minimize deviations — which is especially important for garments with multiple sizes and designs.

This level of precision helps reduce fitting issues and improves final product quality.

b. Time Savings and Batch Scaling

Auto cutters operate much faster than manual blade cutters. They can slice through thick stacks of fabric in minutes while maintaining quality. This enables manufacturers to handle high-volume orders without proportionally increasing workforce size.

c. Enhanced Safety and Risk Reduction

Manual cutting involves sharp tools and physical effort — both risk factors for operator injury. Auto cutters encapsulate cutting blades within guided systems, improving workplace safety.

d. Waste Reduction and Cost Savings

Because auto cutters use optimized patterns from CAD systems and achieve precise cuts, waste fabric is reduced. Less waste translates into significant material cost savings — particularly when handling expensive textiles. (automactec.com)

- Synergy: How CAD + Spreaders + Auto Cutters Transform Production

Individually, CAD, spreaders, and auto cutters provide major benefits. But when integrated into a holistic workflow — from digital pattern creation to automated spreading and precision cutting — the collective gains are exponential:

a. End-to-End Process Automation

Digital designs feed directly into cutting systems. Automated spreaders and cutters work in harmony to produce garments without interruptions caused by manual errors or time lags.

b. Lean Manufacturing and Reduced Lead Times

Lean manufacturing principles demand reduced waste, faster processing, and continuous improvement. Automated systems support these principles by streamlining production stages and minimizing rework.

c. Enhanced Quality Control

Digital workflows also allow real-time tracking and analytics — enabling managers to identify issues early, make adjustments quickly, and maintain consistent quality standards.

d. Competitive Edge in Fast Fashion

In fast-moving markets where trends shift weekly, speed and flexibility are paramount. Automated processes allow manufacturers to adapt designs, test samples, and scale production rapidly to meet demand.

- AutoMac Technology: Integrating Automation for Efficiency and Productivity

Now that we understand the individual technologies, let’s explore how AutoMac Technology Ltd. elevates garment manufacturing by integrating CAD, spreader, and auto cutter systems into a complete solution. (automactec.com)

a. Comprehensive CAD and Cutting Solutions

AutoMac provides high-quality Gemini CAD software for pattern design, marker making, and cut planning — enabling digital setup from the very beginning of production. (automactec.com)

Their systems allow:

• Advanced pattern drafting and grading

• Efficient marker planning that maximizes fabric usage

• Seamless output to cutting machines

By using top-tier software, AutoMac eliminates manual bottlenecks and improves accuracy.

b. Automated Spreading Machines for Higher Throughput

AutoMac partners with industry-leading spreader manufacturers to offer automated spreading systems that handle all kinds of fabrics — from single jersey knit to woven materials. (automactec.com)

These spreaders ensure:

• Consistent fabric tension

• High-speed operation

• Reduced manual intervention

The result is faster preparation for cutting, reducing bottlenecks in one of the most time-consuming steps of garment production.

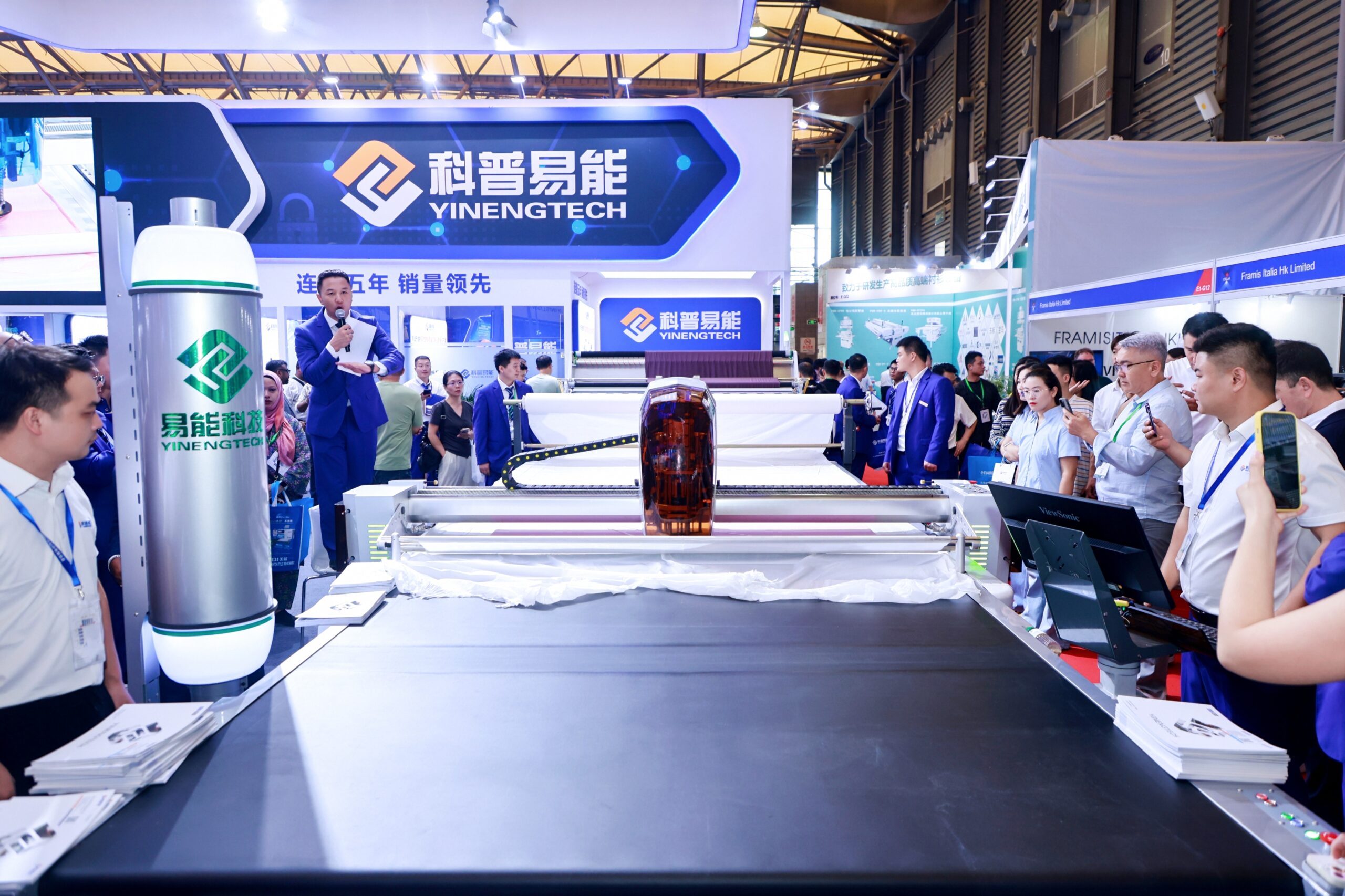

c. Advanced Auto Cutting Technology

AutoMac supplies auto cutting machines from top manufacturers like YINENG TECH — machines capable of handling precise cuts with minimal waste. (automactec.com)

Benefits include:

• Fast cutting speeds

• Precision across multiple fabric types

• Integration with CAD output for flawless execution

For garment manufacturers, this means faster lines, better quality, and reduced rework — all contributing to higher productivity.

d. Additional Process Automation

AutoMac’s portfolio goes beyond just CAD, spreaders, and cutters. They also offer:

• Fabric inspection systems to check for defects before cutting

• Fabric relaxing and shrinking machines to optimize fabric behavior

• Auto leveling and marking machines to reduce paper waste and speed planning (automactec.com)

Each component contributes to closing gaps in traditional workflows — making the production environment more efficient and more consistent.

e. Implementation Support and Continuous Improvement

What sets AutoMac apart is not just hardware and software, but the support services that accompany them:

• Factory auditing and analysis to identify gaps

• Lean tools to optimize workflows before installation

• Post-installation tracking and performance analysis (automactec.com)

This approach ensures that manufacturers don’t just adopt technology — they implement it in ways that deliver measurable results.

- Real World Impacts: What Manufacturers Can Expect

Across the textile and garment industry — from Bangladesh to global production centers — automation is rapidly changing the equation. According to recent industry updates, advanced automatic fabric-cutting machines with repeat-cutting capabilities are significantly reducing processing times and boosting productivity, even with higher upfront costs. (The Financial Express)

a. Faster Cycle Times and Output

Automated cutting and spreading can reduce what used to be bottleneck operations by dramatic margins. Faster cycle times help factories meet tighter delivery schedules and handle larger order volumes without increasing labor costs.

b. Better Fabric Utilization

Thanks to smart CAD and optimized cutting markers, fabric utilization improves — meaning less leftover waste and more garment pieces from the same material.

c. Improved Quality Control

Automated inspections and precise cutting reduce defects, ensuring garments reach customers with consistent quality — a must for brands competing in demanding markets.

d. Labor Optimization and Skill Redeployment

Automation doesn’t necessarily replace human roles — it elevates them. Skilled workers can be redeployed to higher-value tasks like quality assurance, data analysis, and advanced machine supervision.

- Challenges to Consider

While the advantages are clear, there are considerations for any manufacturer thinking of adopting these technologies:

Investment and ROI

The upfront cost for CAD systems, spreaders, and auto cutters can be significant. However, the return on investment (ROI) often materializes quickly through reduced labor costs, less waste, higher throughput, and improved quality metrics.

Training and Change Management

Introducing automation requires training staff to operate new systems and adapt to digital workflows. Partnering with companies like AutoMac that provide ongoing support and training can mitigate this challenge.

Maintenance and Technical Support

Automated systems require regular maintenance and technical expertise. A support partner is crucial to ensuring uptime and rapid troubleshooting.

- Future Outlook: Automation and Beyond

The trajectory of garment manufacturing is clear: automation and digital technology will play an ever-growing role. Here’s what the near future looks like:

a. Smart Factories and IoT Integration

Factories with interconnected machines and real-time data flows will become more common — allowing predictive maintenance and even smarter production decisions.

b. AI-Driven Quality and Design Enhancements

Artificial intelligence will augment CAD systems, enabling automatic design suggestions, predictive pattern optimization, and even defect detection during cutting.

c. Sustainability Through Technology

Automation reduces waste and optimizes energy use — key components of sustainable manufacturing. As sustainability becomes a priority for brands and consumers alike, technologies like CAD, automated spreaders, and cutters support those goals.

Conclusion

The benefits of CAD software, fabric spreaders, and auto cutters in garment manufacturing are manifold:

• Faster turnaround times

• Higher accuracy and consistency

• Reduced waste and higher profitability

• Safer and more efficient production environments

• Enhanced scalability and flexibility

When integrated through strategic partners like AutoMac Technology Ltd., these tools don’t just improve isolated parts of the production process — they transform entire workflows, elevate worker roles, and position factories for success in the competitive textile marketplace. (automactec.com)

For garment manufacturers seeking to thrive in an era of rapid change, investing in automation isn’t just smart — it’s essential.